Air motor control

Air supply for air motor

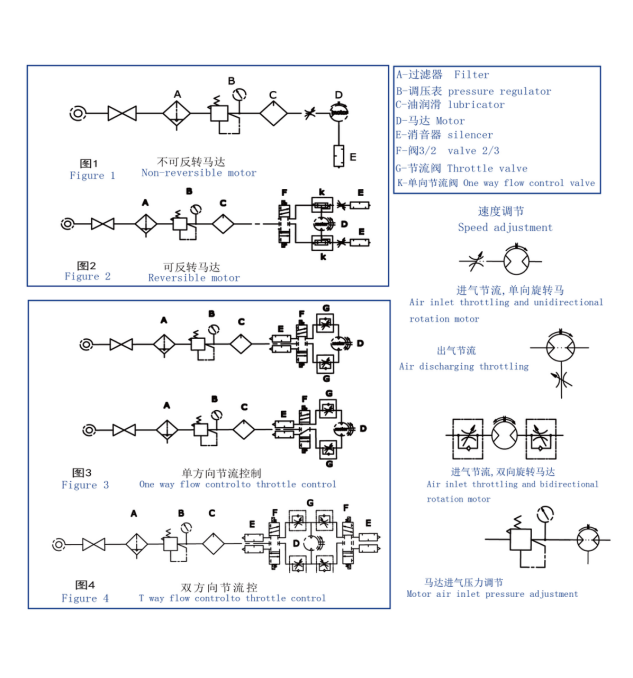

1. The air to be supplied to the motor must be filtered and depressurized. Directional control valves need to supply air to the motor and rotate the motor when needed. Such valves can be pneumatically controlled, electronically controlled, or mechanically controlled.

2. When the motor is used in applications that do not use bidirectional rotation, it is sufficient to use a 2/2 or 3/2 valve to control it. For motors that can rotate in reverse, a 5/3 or two 3/2 valves are needed to ensure that the motor has a compressed air supply and residual air exhaust.

3. If the motor is not used for directional rotation, the flow regulating valve can be installed in the air supply line to adjust the speed of the motor. If the motor is used for reverse rotation, a flow control valve with an internal one-way function needs to adjust the rotation in each direction. The valve with internal one-way function allows air to be discharged from the residual air vent of the motor to the exhaust port of the control valve and then discharged.

4. The compressed air supply must have a large enough pipe and valve to ensure the maximum torque of the motor. At any time, the motor requires a supply pressure of 6 bar, and when the pressure is reduced to 5 bar, the power is reduced.

Motor throttling

The most common way to reduce the speed of an air motor is to install a flow control valve at the air intake. When the motor is used with air intake, it can also be used for exhaust port. Flow regulation is also used on the main exhaust port, which allows speed control in both directions.

pressure regulation

Speed and torque can also be adjusted by installing a pressure reducing valve at the upstream air supply. When low-pressure air is continuously supplied to the motor and the motor decelerates, a low torque is generated on the output shaft.

Assisted throttling produces low speed in one direction, but maintains torque when decelerating. The main air intake throttling can be achieved in both directions, but the torsion of the main air inlet pressure is maintained when decelerating, and the torque is reduced when the motor decelerates, and the speed is also reduced.